How do you program a general, comprehensive process for inspecting the evolution of engineering structures?

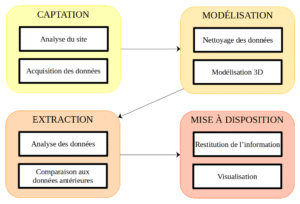

The development of data acquisition technologies (visible and multispectral sensors, lidar, etc.), data acquisition vectors (satellites, aerial, terrestrial and underwater drones) and the efficiency of photogrammetric modelling engines have paved the way for accurate, compliant 3D modelling of engineering structures [1]. At the same time, signal processing techniques now make it possible to extract the required information from the mass of information acquired during a capture, and to obtain meaningful comparisons between different acquisitions. Extending Olsen’s approach [2], it is thus possible to establish a complete process for the inspection of engineering structures with time tracking, and thus to put the relevant information and the means for its visualization at the service of the human expert (figure 1.). Throughout this process, however, it is necessary to ensure that the various phases are organized, consistent and harmonized, so as to guarantee the reliability of the information.

Figure 1: Inspection phases in sequence

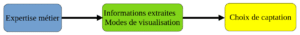

The description of these four steps is completely dependent on the user’s business expertise; in practice, it’s the understanding of the expert’s needs (in terms of restitution of the information that is useful to him or her) that leads to the description of the extraction of the necessary information, which in turn requires the identification of modeling methods, followed by Captation protocols. Ultimately, data capture (formalized by a CCTP) is the result of this design process (figure 2).

Figure 2: Logic of choices

Phase one: Capture

Above all, this phase must be carried out in compliance with current legislation and in optimum safety conditions for all those present on site (operators and users).

Capture is an essential step, since the quality of the raw data determines the accuracy of the entire processing chain. The nature of the raw data (images, lidar points, etc.), the acquisition mode (airborne, ground-based or other, manual or automatic, etc.) and the various parameters (image overlap rate, travel speed, control points, etc.) must be carefully selected according to the following criteria:

- the site (its nature, extent, geometry, environment) ;

- information sought (type, scale) ;

- of the required precision.

Second phase: Modeling

Data cleansing provides reliable data on which to build a 3D model of the structure.

The modeling step is not necessarily necessary, but it offers two possibilities:

- Extract 3D information (polylines, structural movements, etc.)

- Visit the site’s digital twin

In the case of lidar capture, we obtain sets of points that need to be combined into a single cloud, while in the case of optical sensor capture, photogrammetry is used to build a point cloud modeling the site.

The use of control points makes it easy to measure model accuracy.

Phase three: Information extraction

Information useful to the expert must be brought to his attention automatically and rapidly. It can be extracted from :

- raw data

- 3D model from raw data

using tools [3] :

- signal processing and classical geometry

- neural networks

During this stage, the quality of the extractions is monitored to provide a confidence index for the fourth phase.

In the event of a new inspection of a structure, the new information is compared with the previous one in order to identify and quantify any changes.

Phase four: Restitution and visualization

Once useful information has been extracted from the mass of raw data, it must be presented to the human expert in a relevant way.

The quality of the extractions is then translated into a confidence index, enabling the expert to make informed decisions. In order to remove any doubt, access to raw data is essential, enabling the expert to

The evolution measures are also presented, so that the expert can monitor the structure over time.

[1] Arnadi Dhestaratri Murtiyoso, “3D survey and classification of point clouds of the

built heritage”, 2020

[2] Olsen, Michael & Kuester, Falko & Chang, Barbara & Hutchinson, Tara, “Terrestrial Laser

Scanning-Based Structural Damage Assessment”, Journal of Computing in Civil Engineering,

2010

[3] Romero, L.M.; Guerrero, J.A.; Romero, G. “Road Curb Detection: A Historical Survey”.

Sensors 21, no 21, 2021